What is CNC Machining?

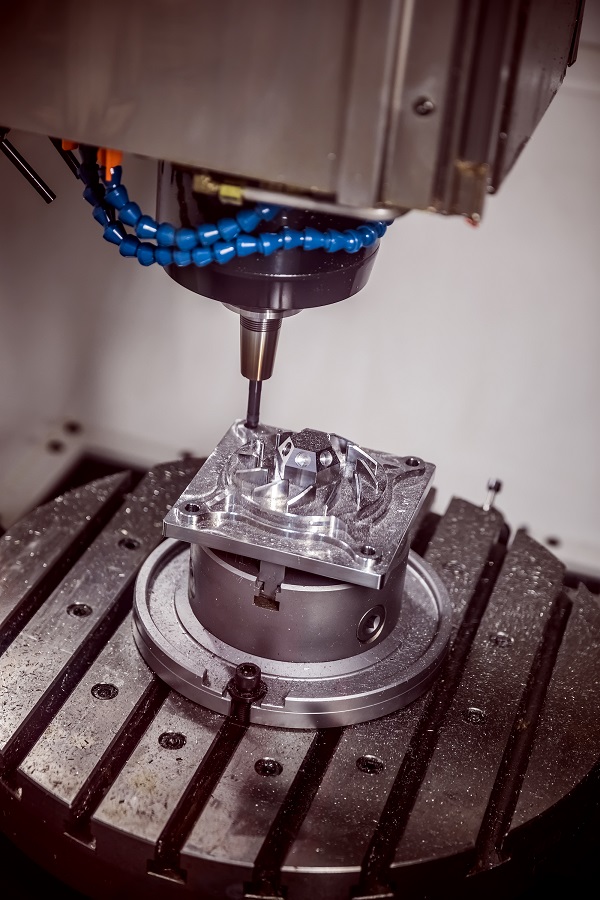

Computer Numerical Control machining allows us to perform a wide variety of manufacturing activities with improved accuracy, increased productivity, greater reliability and complete precision.

Machinery – We use the best and latest equipment on the market, designed to meet with ease our client’s most complex and unusual needs. From working with extremely tight tolerances, exotic materials, achieving planarity using high cutting feeds and speeds to stability, rigidity and optimized tool performance.

Volume – From mass production, to low volume to rapid prototyping of single components, sometimes ready in less than 24h, we have no minimum requirement to help you get the job done and provide assistance along the way.

Leadtime – With the latest technology on the market, optimized process and 24/7 operational facility, in addition to our cross-trained employees with 20+ years of combined experience in design, programming, setup and operation, at KratoStructures we can have your detail ready in less than 24h.

Competitiveness – Often times there’s plenty of room for design and programing optimization, which in turn reflects on the cost of manufacturing. By having the knowledge, experience and latest tools available in the field, we’re able to offer the best and most competitive prices to help our clients stay in budget.

Materials – The same way we handle aluminum, steel and plastic with no difficulty, we also have the ability to work with a wide range of exotic materials based on your needs and requirements.

Design – Experienced and professional staff can guide you from the initial stage of your design phase till its completion or offer optimization where possible of an already existing one.

Pride – You should expect nothing short of high quality, timely completion of your order and exclusive customer service from the moment you reach us, till you get your packaged delivered to your door.

Where is CNC machining used?

CNC machined components are found everywhere around us and serve a wide variety of industries. Semiconductor, automotive, medical, aerospace, defense and many others are heavily reliant on the ability of CNC machines to manufacture numerous intricate parts and key components for their end products. Some of those industries utilize CNC machining to meet their mass production needs, but many require custom created components in low volumes for precise use and specific application.

Semiconductor Industry

Machine parts for wafer handling robots

End effectors

Precision chucks

Components for process and inspection stations

Medical Industry

Implants

Orthotic devices

MRI machines

Medical instruments

Aerospace Industry

Manifolds

Bushings

Landing gear parts

Antennae

Transportation Industry

Shipping vessels

Freight trains

18-wheel transport trucks

Passenger vehicles

Oil & Gas Industry

Pins

Rods

Valves

Cylinders

Military & Defense Industry

Communications components

Brackets

Transportation components

Plane parts

Marine Industry

Insulating cases

Propellers

Engine components

Boat parts